Successful manufacturing is all about minimizing waste and optimizing productivity. Many different tools have been applied over the years to enable the goal of Lean Manufacturing, including Kaizen, Visual Factory, and Poka Yoke. While these concepts may all seem attractive to owners, investors, and even academics, they don’t necessarily mean much to operators on the factory floor. Moreover, some of these phrases – lean manufacturing in particular – carry some weighty connotations. When employees hear that their manager wants to go “lean”, they may start worrying about their job security. That’s why RMA has developed its own approach to optimization, called Smooth Flow.

What is Smooth Flow?

Smooth Flow is a process where all the information that is relevant to a manufacturing job is delivered consistently and smoothly through every step of the process – from sales, to planning and design, all the way through to manufacturing engineering and then production. This approach ensures clear communication, ownership and accountability at each step of the process, and seamless handovers.

The process starts with leadership. Project leaders set firm goals at the outset, which are then clearly communicated to everyone involved, and re-enforced regularly.

Peter Lawson, Global Technical Director for RMA Automotive, believes there’s no such thing as repeating a goal-oriented message too many times. By repeatedly driving the point home, he says, “everyone understands what we’re doing, all are aligned, and accountability is seen at all levels of the organization.”

With the entire team working towards the same end, all involved feel a genuine sense of joint ownership – and pride in a job well done.

Lawson prefers to always use terms that are self-evident to everyone, including production operators. This is why his team identifies with Smooth Flow rather than the more complex Lean Manufacturing. It’s not that Lean Manufacturing doesn’t have great tools and processes, rather it’s about hand selecting those tools and processes with maximum leverage for RMA’s business and packaging them in such a manner that all can easily understand and align to.

Of course, Smooth Flow involves much more than general commitments toward cohesive messaging and teamwork. It also has many practical tools and processes in its execution.

Capable processes, visual factory, and error-proofing

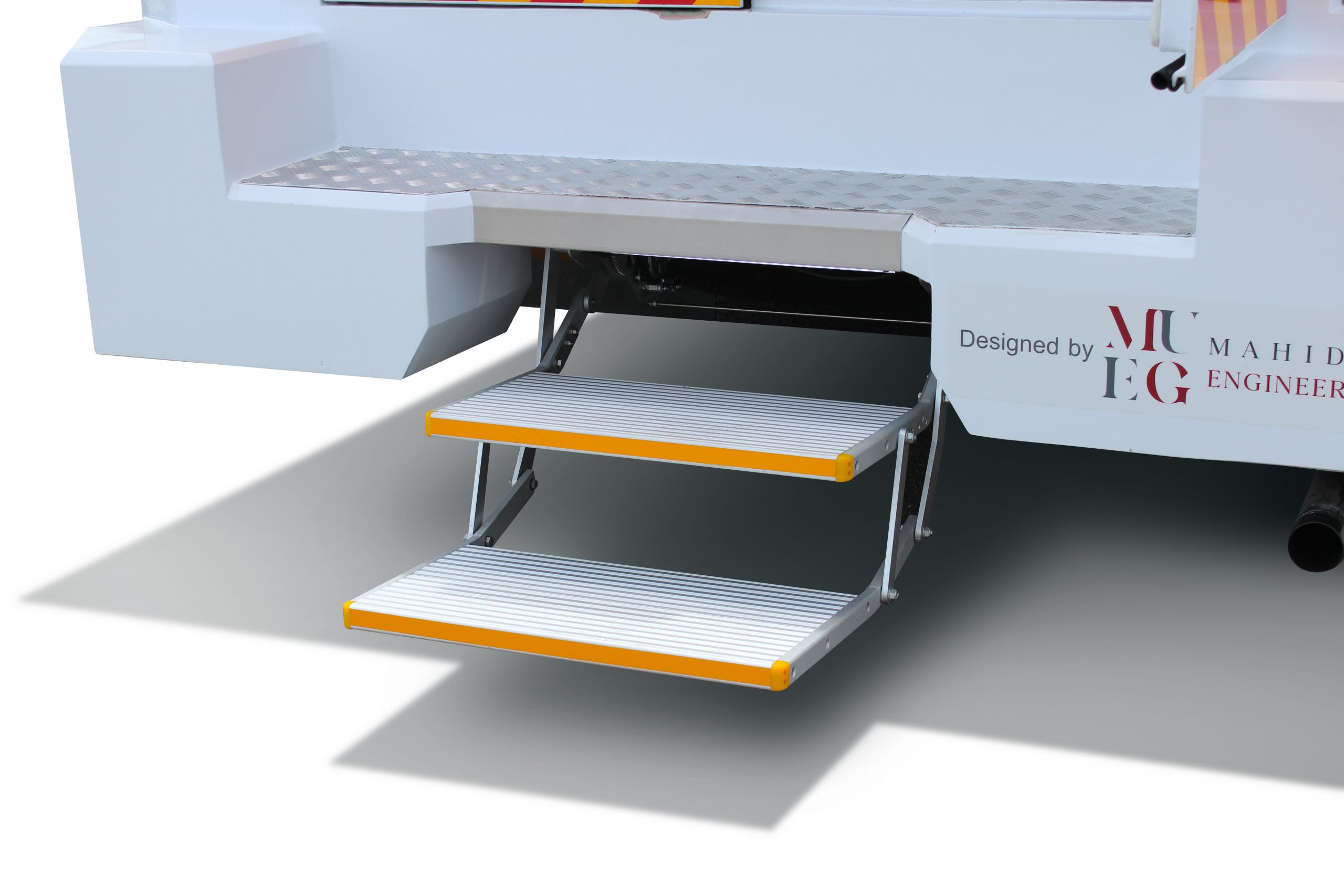

Creating a capable process involves taking a given task and organizing it in such a way that guarantees its successful completion. As Lawson explains it, when a capable process is in place, any able-bodied person that has been given the right training, the right process, and the right tools can complete the job without ever making a mistake, because mistakes have been rendered highly improbable during the planning and setup stages.

It starts with a capable design, sound manufacturing engineering development with key operator engagement, a robust launch pre-build process and a series of simple, well-known tools (5s, Visual Factory and Error Proofing – Poke +Yoke).

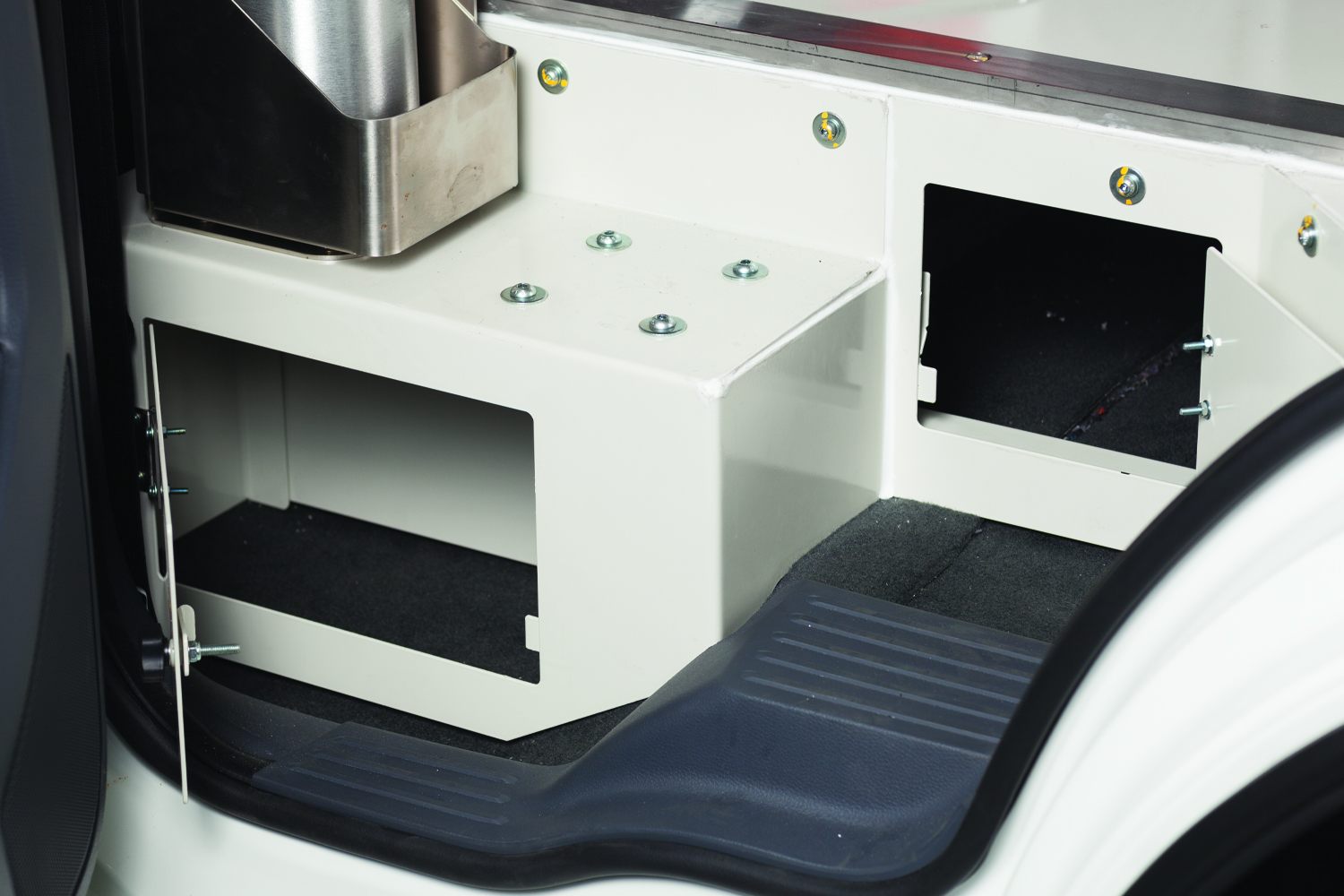

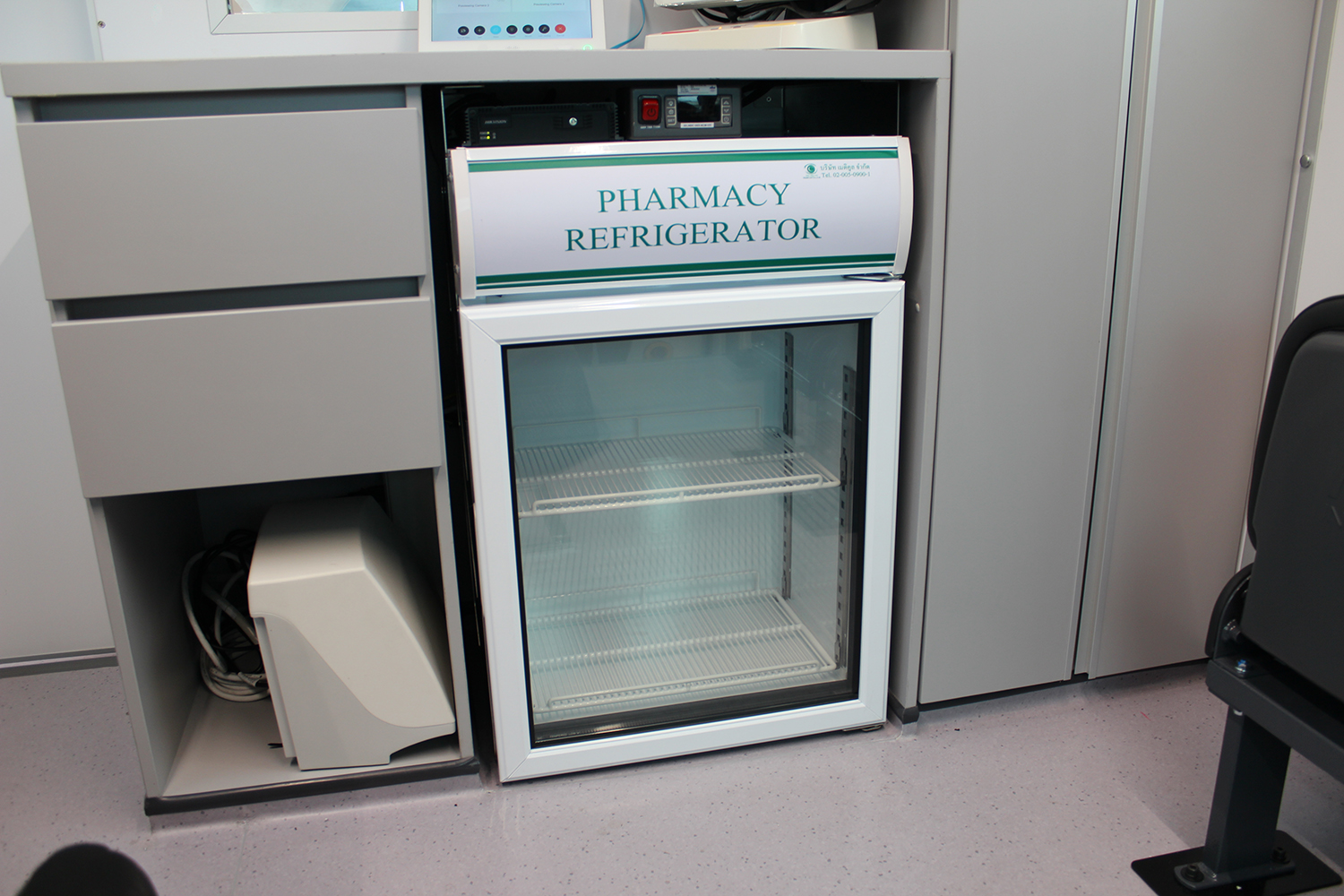

Visual factory helps make each task straightforward. In a visual factory, simple tools such as color coding, labelling, and specifying a standard location for everything helps make the process self-evident for operators. This organizational strategy allows even highly complicated processes to become clear for the workers.

Another key tool is error-proofing. When a manufacturing process is error-proofed, tasks are set up so that cannot be completed in any other way but the correct one. For example, two parts that are meant to connect together can only connect with each other and no other part.

These are tools well-known in Lean Manufacturing.

Making 1+1+1=5

In Smooth Flow, there are 16 elements, representing 16 areas of the business that contribute to Smooth Flow. These include Sales, Program Management, Product Development, Purchasing, Supplier Technical Assistance, Manufacturing Engineering, Production, Finance, etc. All the different elements that play a role in the launch of a product fit together like the pieces of a jigsaw puzzle. When the various components of a manufacturing job don’t fit together cohesively, then the outcome is less than expected.

With the benefit of a Smooth Flow approach, enhanced in turn by motivated teams committed to reaching a common goal, the effective quality and quantity of output is multiplied. Synergy between well-functioning teams adds unexpected value to all the other areas of the factory.

Smooth Flow has been a game-changer for RMA, with benefits that are easy to see. As Lawson puts it: “When you go into a plant, and everything is flowing smoothly, you can intuitively feel it.” Such innovation on the production front allows RMA to deliver customizable and consistently durable products for its customers around the world.