NEWS

Beyond The 15 - RMA Automotive South Africa Celebrates 15 Years of Engineering Excellence and Innovation

South Africa, November 15, 2023 – Special Vehicles Manufacturer, RMA Automotive South Africa (RMAA SA), proudly marked its 15-year anniversary this week. Since its inception in 2008, the company has consistently demonstrated a commitment to excellence and innovation, shaping the future of mobility through advanced engineering and strategic partnerships.

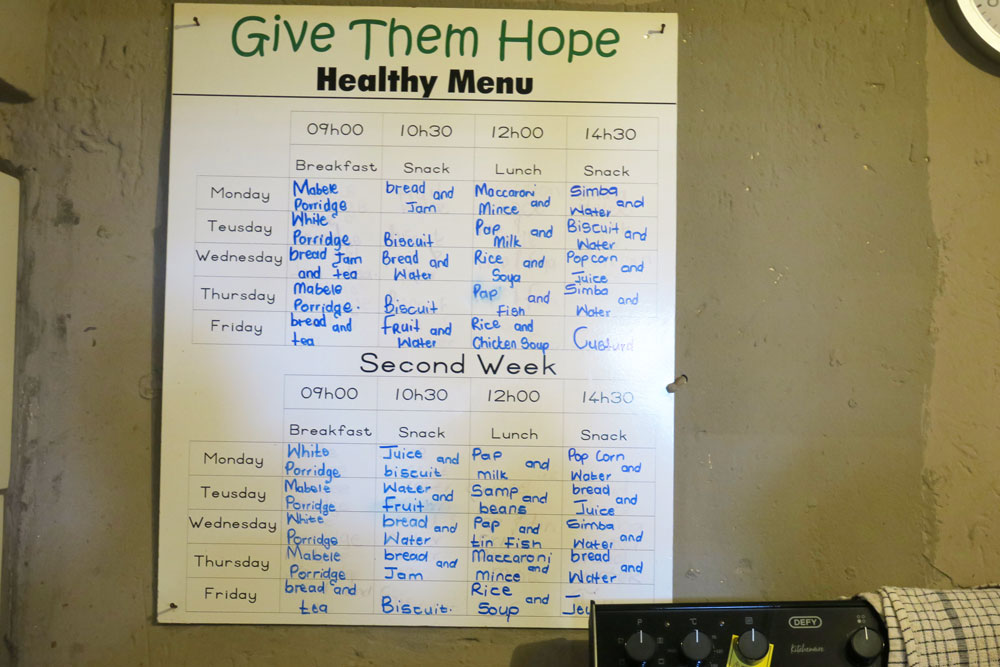

Commemorating the anniversary with the theme, ‘Beyond the 15 – The Future of Mobility Reimagined’, captures the essence of its forward-looking approach in modifying vehicles for export markets, commercial fleet customers, aid organizations, and government agencies.

Embedding Strategic Expertise in South Africa for Africa

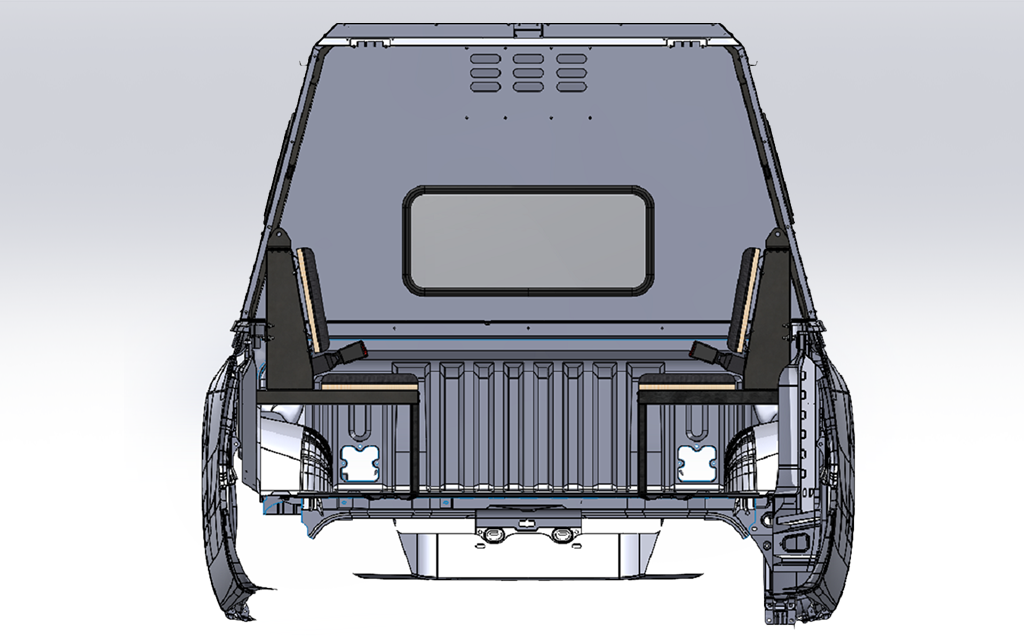

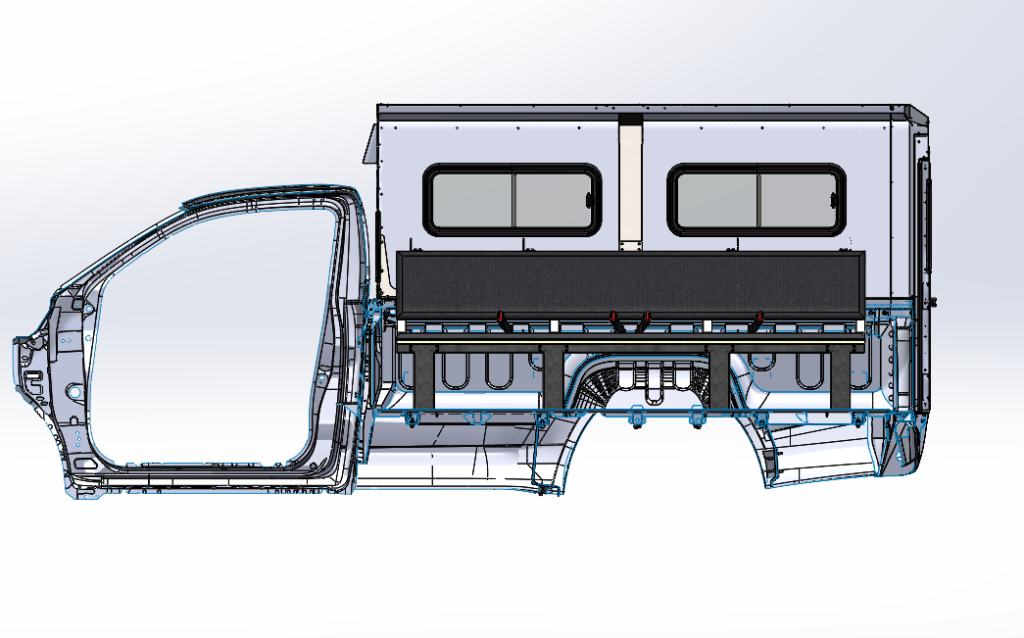

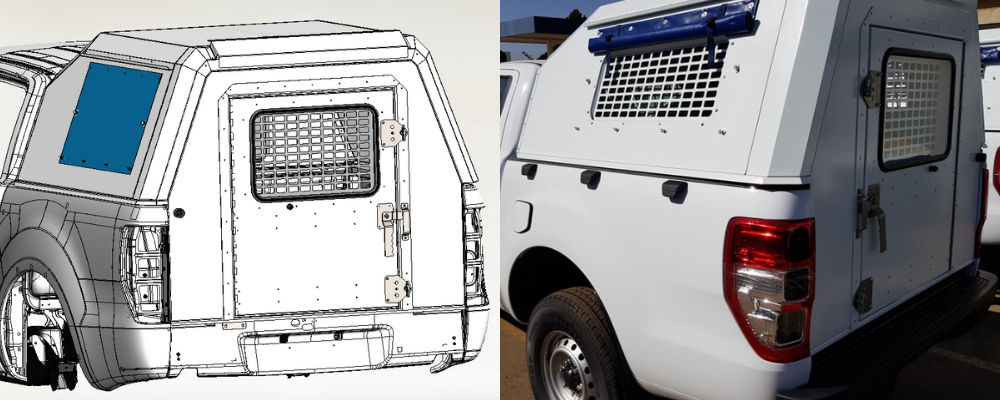

RMAA SA stands at the forefront of automotive innovation as a distinguished vehicle modifier, showcasing its expertise in transforming a diverse range of vehicles. From internal combustion engines to advanced technologies like battery-electric vehicles, the specialized vehicles have engineered technologies for delivering power and propulsion solutions to OEMs (Original Equipment Manufacturers) and a multitude of fleet customers.

The business has renewed its determination and purpose to become an innovative company leading in mobility solutions, and a global player with a balanced footprint across Africa.

“Over the past 15 years in South Africa, we’ve evolved, adapted, and grown. We’ve overcome challenges, embraced change, and seized opportunities. Our success is a testament to the dedication and hard work of every individual who has been a part of this remarkable journey. It is the result of the unwavering support of our clients and partners, and the trust and loyalty of our customers,” said Brendan Londt, Country Manager at RMAA SA.

“Throughout the years, RMAA SA has always strived to be at the forefront of technology, safety, and agility to meet our customers’ requirements and offering them solutions to meet their needs. And now our ambition is to expand our footprint into Africa; not only will we be contributing to the economic development in new markets but more importantly, we will be providing customers across Africa the same excellent service and products in a timeous and cost-effective manner that our South African customers can attest to,” he added.

This 15-year celebratory event marked a legacy of service of how the company has been pushing the boundaries when it comes to innovative mobility solutions. Attendees at the media breakfast also had the opportunity to inspect RMA Special Vehicles’ capabilities and to see first-hand what the future of mobility entails through unmatched innovation, proven performance, and breakthrough life-cycle economics.

Alan Caugant, RMA Automotive Managing Director Global Manufacturing announced the company’s vision for the future and said: “we are making new commitments to develop in three fundamental areas, namely, vehicle personalization, special vehicles solutions and, development and manufacturing competence to ensure that we achieve our financial ambition of doubling our net revenues by 2030 (over 2022) and sustaining a double-digit adjusted operating income margin throughout the decade.”

An impressive strategic development in Africa markets

Representing RMA Group headquartered in Thailand, Christian Wiedmann, RMA Group Senior Vice President and Managing Director Automotive emphasised that the importance of South Africa in the company’s strategy cannot be overstated. “South Africa’s strategic location on the African continent is and will always be a compelling reason for our strong presence here, he said.”

Wiedmann concluded by addressing the talent skills in the continent, saying, “the talent pool in Africa is vast, diverse, and eager to participate in the global economy. By investing in education, skills development, and fostering innovation, the company will not only uplift the lives of individuals but also enhance the organization’s competitiveness on a global scale.”

###

About RMA Automotive

RMA Automotive is an innovative company leading in mobility solutions, and a global player with a balanced footprint across the globe.

RMA Special Vehicles core competencies are the special vehicle modification solutions, complex conversions, large scale vehicle personalization and CKD assembly.

RMA Special Vehicles are produced at RMA Automotive’s global manufacturing plants in Thailand, Cambodia, Myanmar, Türkiye, Dubai, South Africa, and Australia.

About RMA Group

Headquartered in Bangkok, Thailand, RMA Group employs over 8,000 people and has an operational presence in 14 countries. RMA is the partner of choice for leading automotive, equipment, services, and food brands in Southeast Asia and beyond. Operations consist of the manufacturing of special vehicles, vehicle distribution, retail, and fleet hub services; RMA heavy and agricultural equipment distribution, EFG food franchising and delivery services, engineering, and financial services.